About Me

WHO IS KEERTHI SEPURI?

Welcome to my world of mechanical innovation and design precision. I'm

Keerthi Sepuri, a

Mechanical Design Engineer with a passion for pushing the boundaries of

what's possible in vehicle

engineering. With a relentless pursuit of excellence and a keen eye for

detail, I've been at the

forefront of shaping the future of transportation technology.

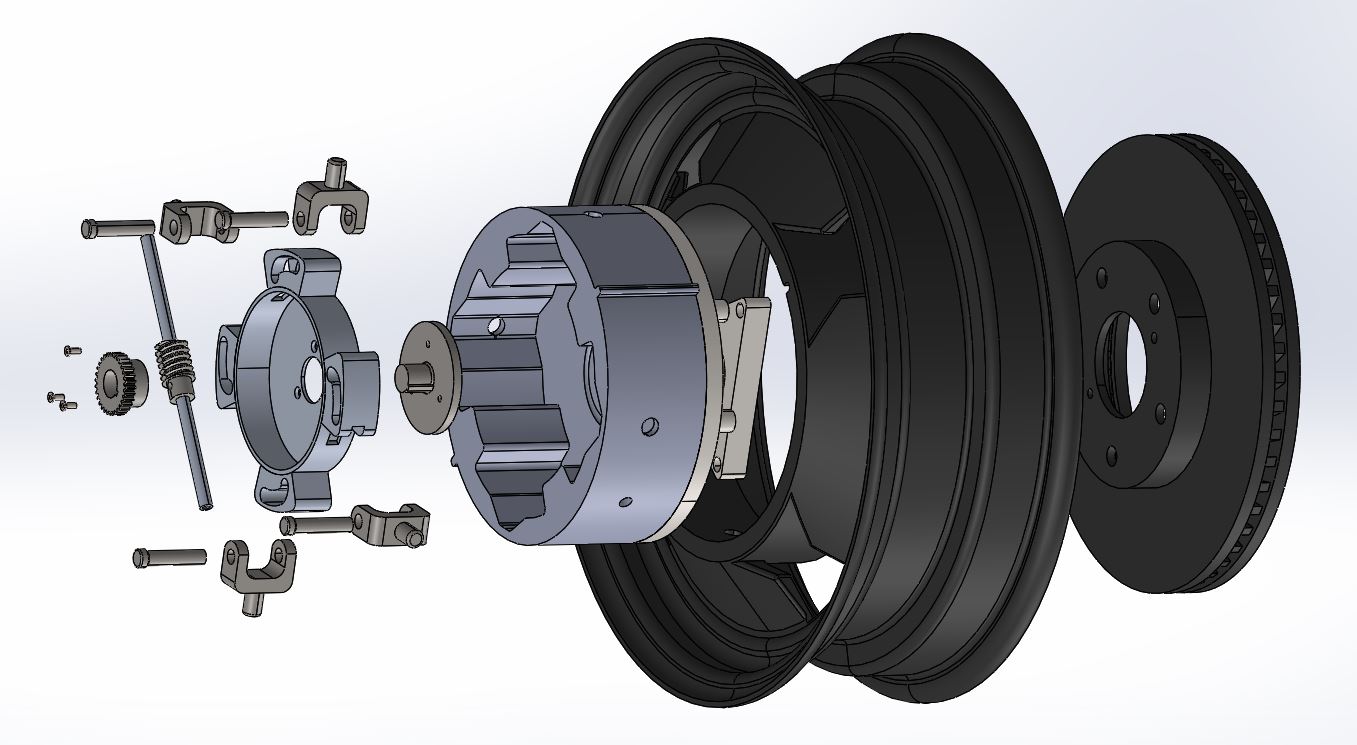

My journey in the industry has been nothing short of exhilarating. From

leading suspension design

projects at Nikola Motors, where I orchestrated the dynamics of Class 8

Semi-Truck suspensions,

to pioneering groundbreaking solutions at Tesla, including the intricate

design of Cybertruck

components, my career has been defined by innovation and excellence.

With a Master's degree in Mechanical and Aerospace Engineering from New

York University and a

solid foundation from Jawaharlal Nehru Technological University, India,

I bring a unique blend of

academic rigor and practical expertise to every project I undertake.

My portfolio is not just a showcase of projects; it's a testament to my

commitment to excellence.

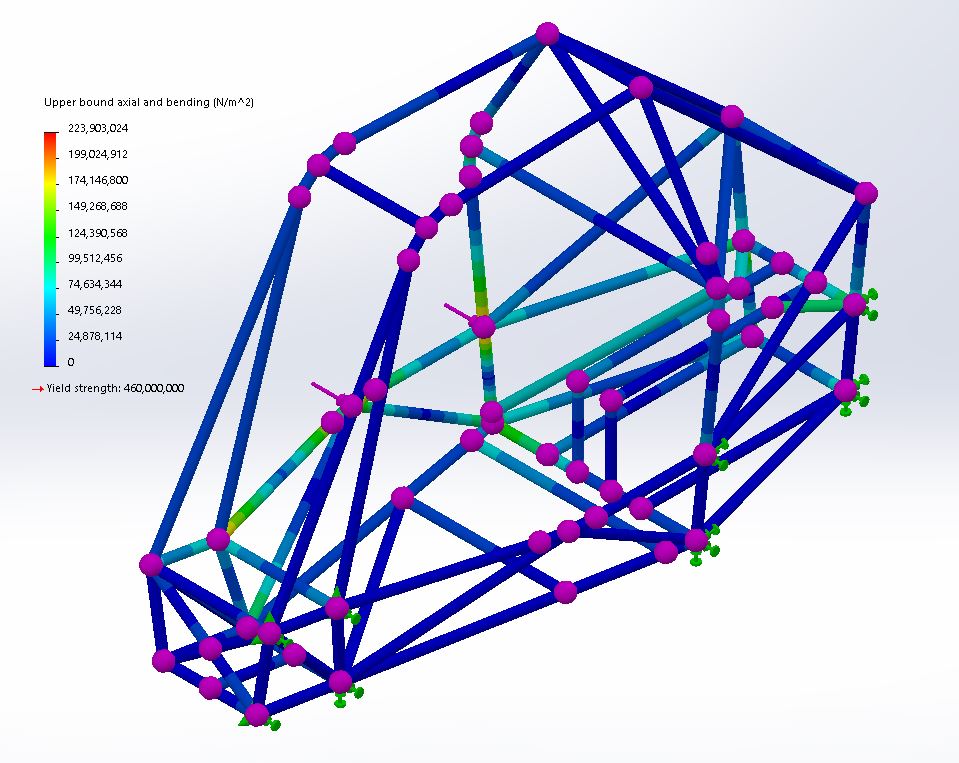

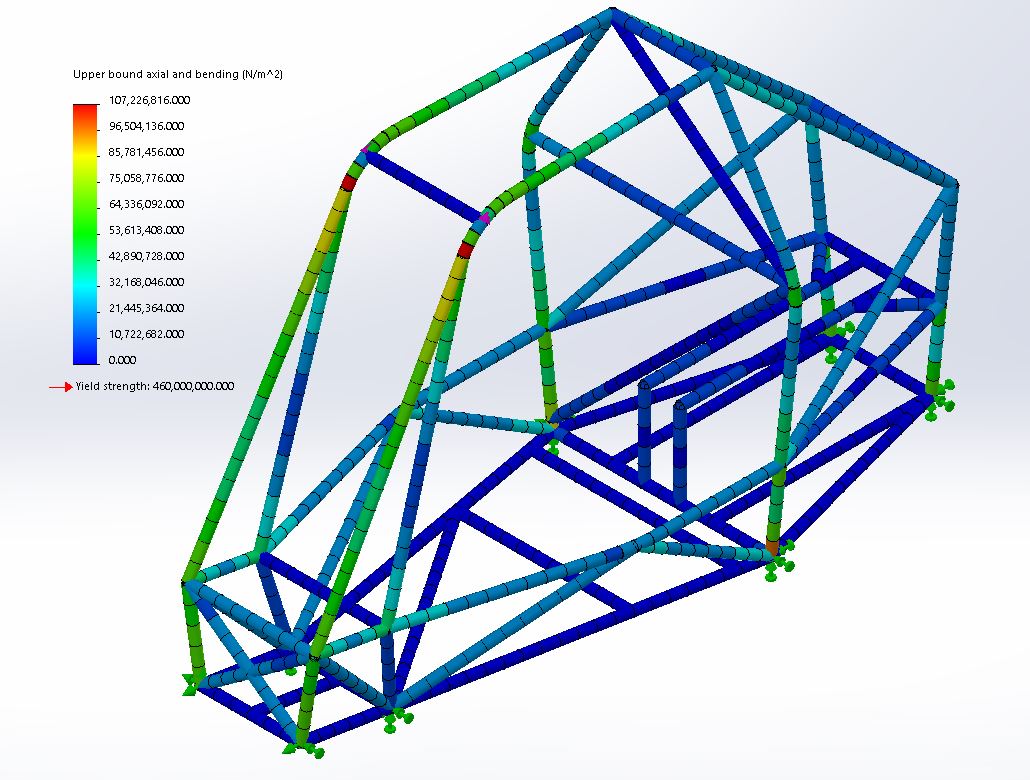

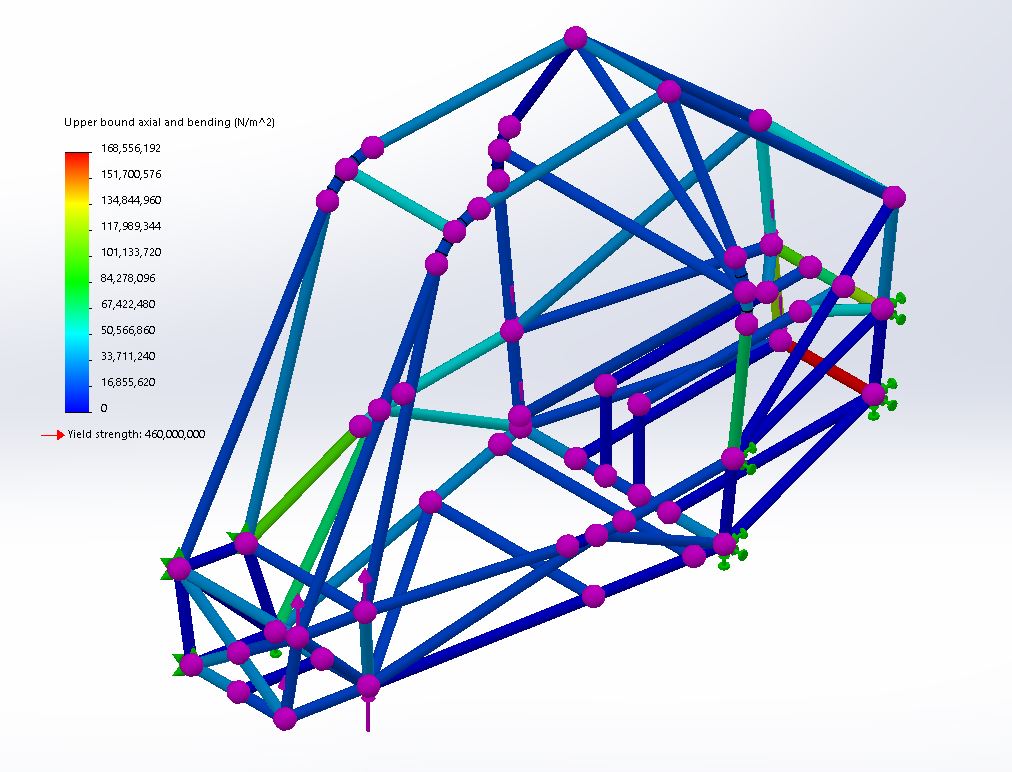

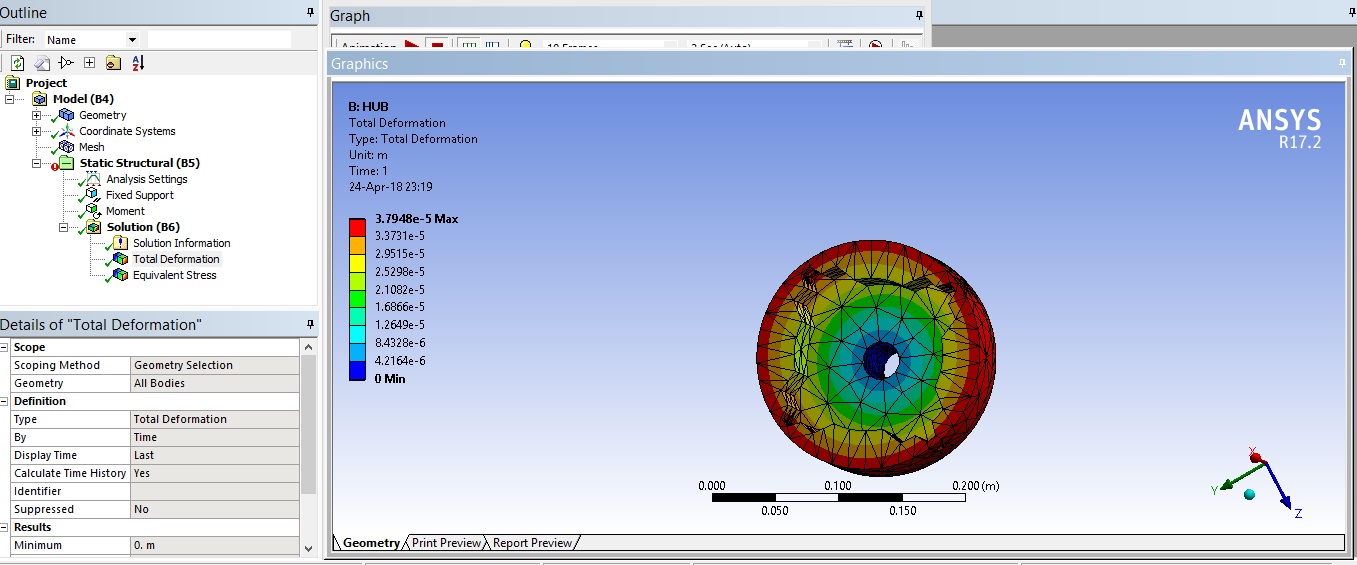

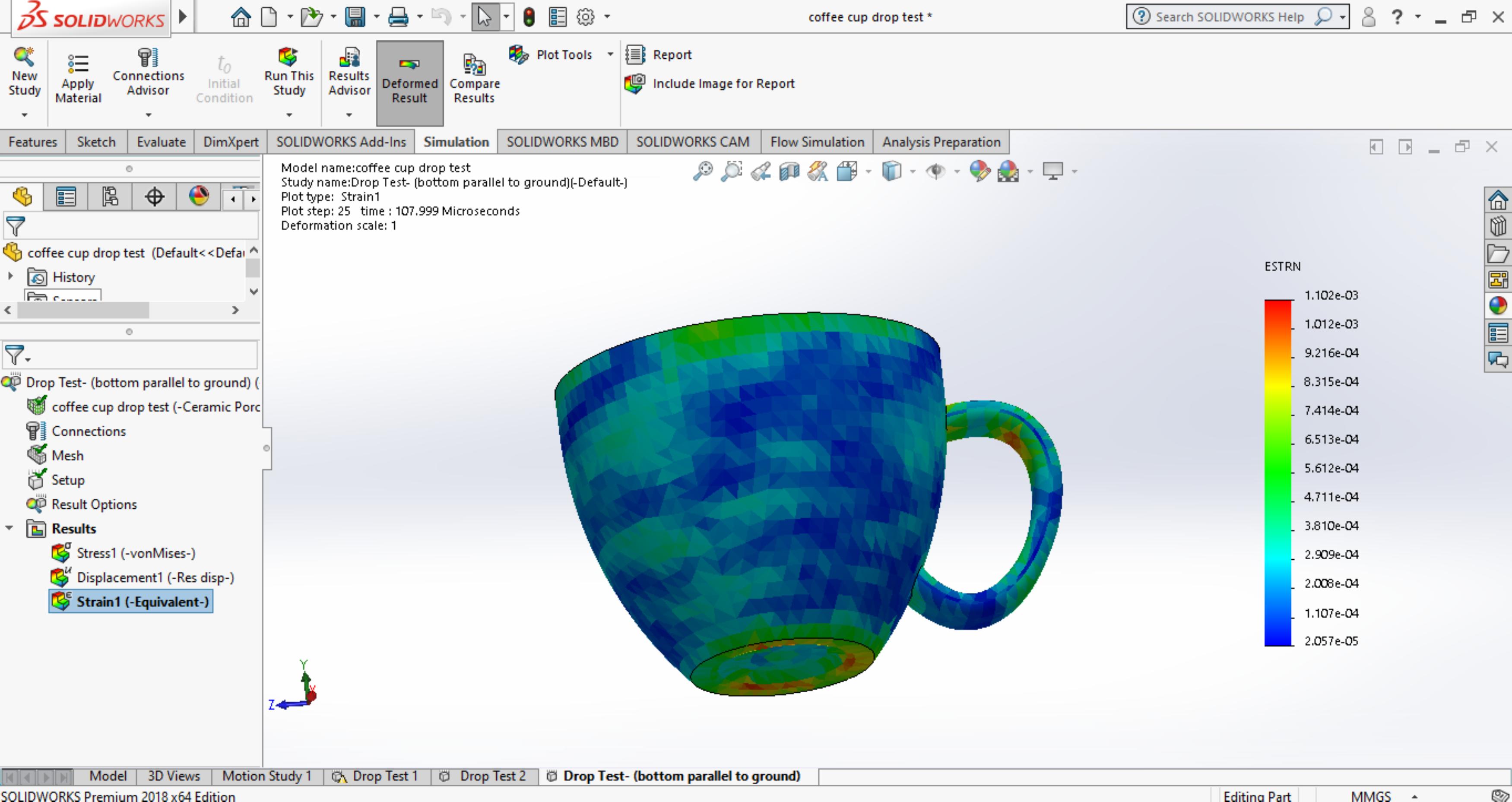

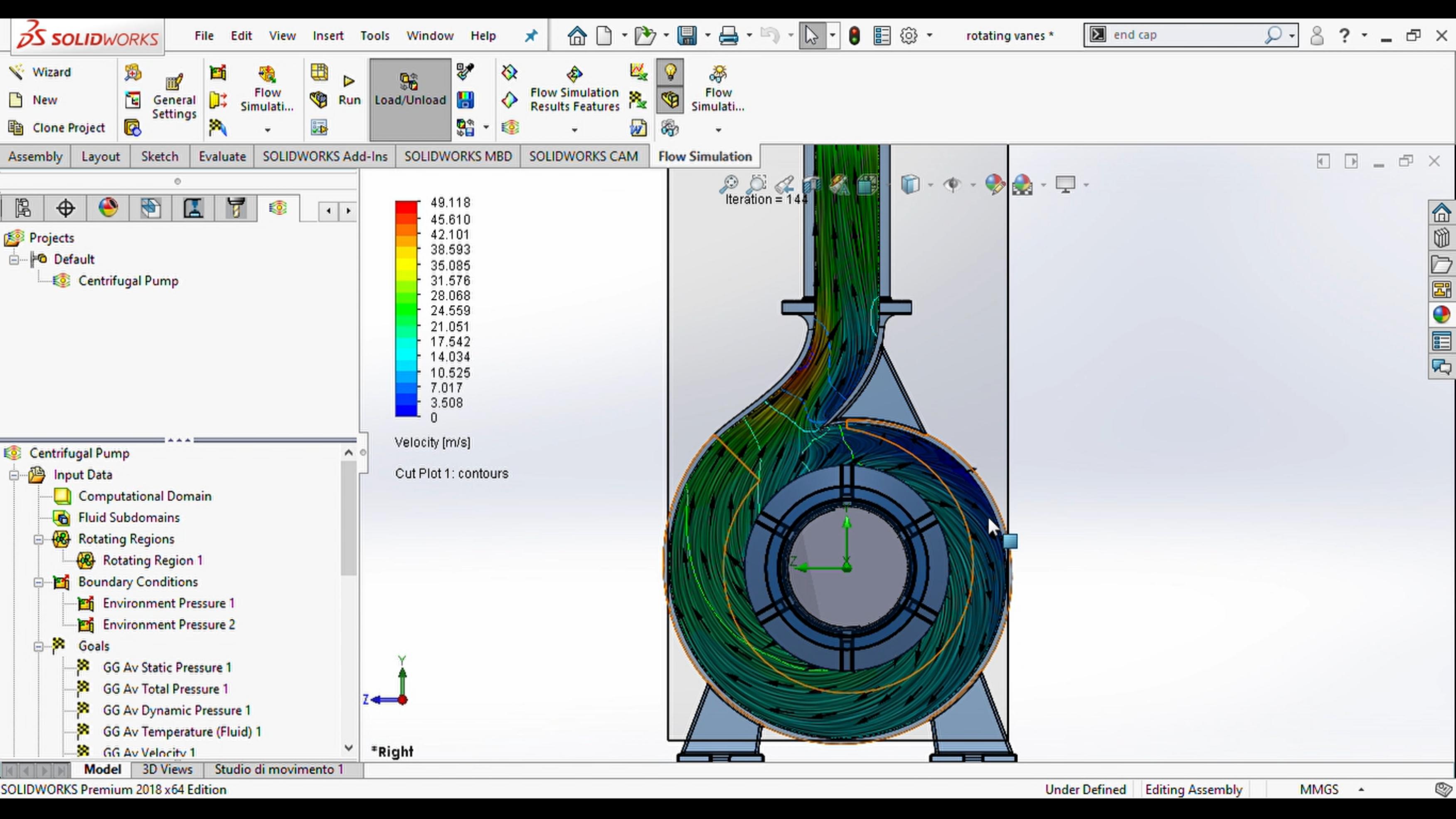

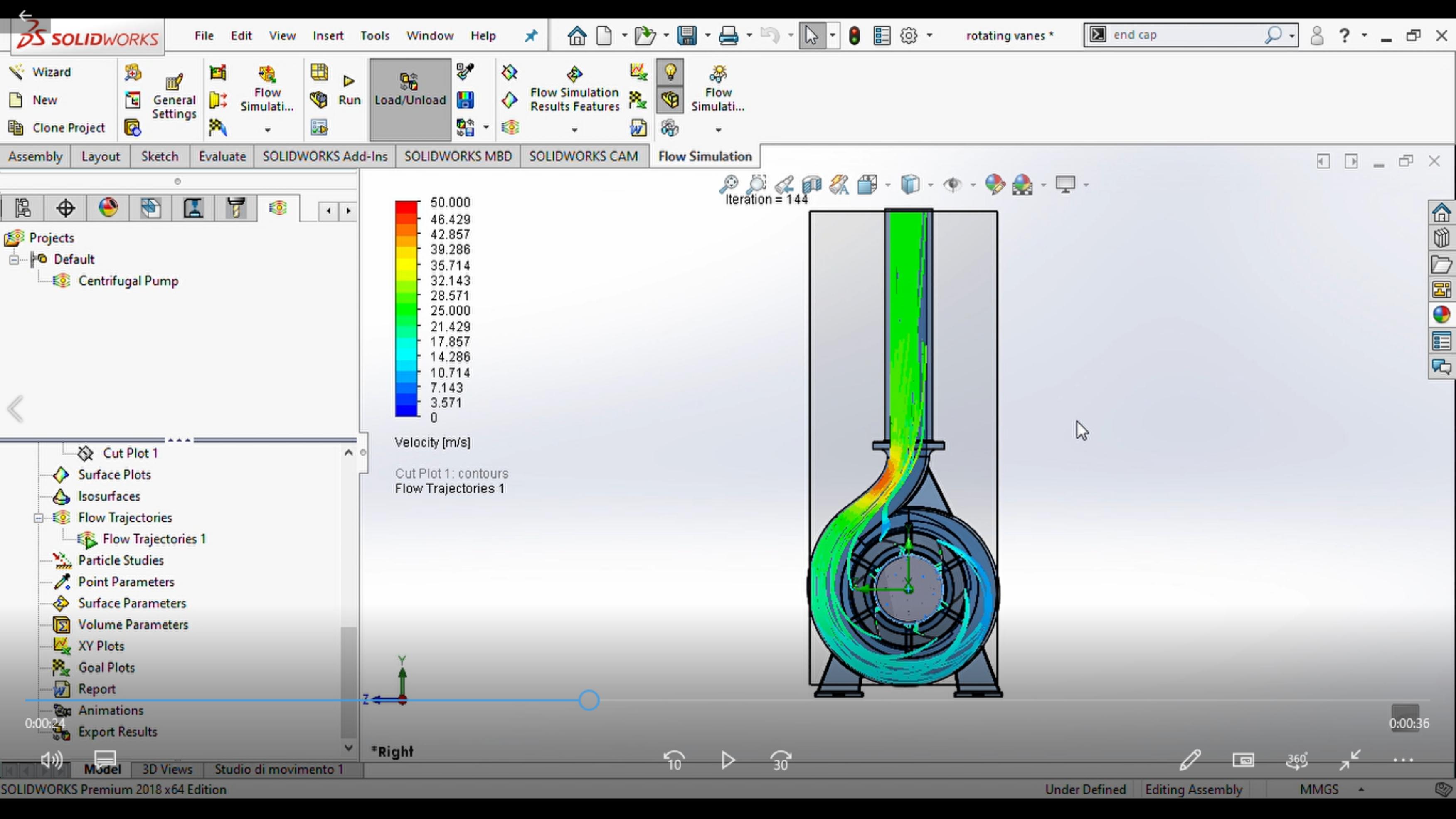

Whether it's optimizing mass and cost for efficiency, conducting

rigorous FEA analysis, or

collaborating seamlessly across multidisciplinary teams, I thrive on

challenges that demand

ingenuity and precision.

But beyond the technical realm, I pride myself on my soft skills—my

ability to communicate

effectively, think critically, and foster strong team dynamics. I

believe that true innovation stems

from collaboration and diversity of thought, and I'm dedicated to

fostering environments where

creativity flourishes and boundaries dissolve.

In a world driven by innovation and fueled by ambition, I stand ready to

embark on the next frontier

of mechanical design. Join me on this journey, where every project is an

opportunity to redefine

what's possible and leave a lasting impact on the future of

transportation.

Let's build the future together, one meticulously designed component at a

time

/1.jpg)

/2.jpg)

/3.jpg)

/4.jpg)

/5.jpg)

/6.jpg)

/7.jpg)

/8.jpg)

/9.jpg)

/10.jpg)

/11.jpg)

/12.jpg)

/13.jpg)

/14.jpg)

/15.jpg)

/16.jpg)

/17.jpg)

/18.jpg)

/19.jpg)

/20.jpg)

/21.jpg)

/22.jpg)

/23.jpg)

/24.jpg)